CANDYKING - Cutting costs and accelerating orders with a new planogram system

Background

Established in 1984, CandyKing is a leading “pick and mix” supplier of natural snacks and candies for over 10,000 retail outlets across the Nordic region, UK, Ireland and Poland. Their business model is based on purchasing candies from various suppliers and providing each customer with an individual assortment list with one price for all products. But CandyKing’s turnkey concept doesn’t stop at delivering the goodies. They even take care of the displays and accompanying store and logistics services.

Keeping supply and demand in balance and not messing up the details in the process is pivotal to CandyKing’s success. And as the business continued to expand, the efficiency of daily operations began to crumble. Time-consuming and mistake-prone processes related to keeping customers’ assortments up-to-date were leading to profit losses.

Ready for change, CandyKing contacted us as Fastdev to implement a new IT infrastructure that could help them optimize both assortment management and ordering processes.

Challenge

When CandyKing contacted us at Fastdev, they had already implemented a home-made planogram planner system in an effort to automate the assortment management process. However, the design was flawed incompatible with their business needs. Furthermore, the planogram planner was unsynchronized with their sales automation tool. This meant that order handling was not based on customers’ actual assortment— a mismatch that was leading sales representatives to order products that were out of stock. Moreover, the sales automation tool’s monthly license fee of about 600 SEK per user was adding up to a staggering sum when multiplied by CandyKing’s hundreds of sales representatives.

Another challenge was the fact that different markets and countries needed to be able to work according to their own business processes. This would require a very customized solution that could handle all operations within one system.

To solve all of theses issues, the Fastdev team would have to replace the incorrectly designed and expensive systems, automate processes, create user-friendlier interfaces, and figure out a way to reduce costs related to user licenses and inefficient sales processes.

Development Process

Step 1

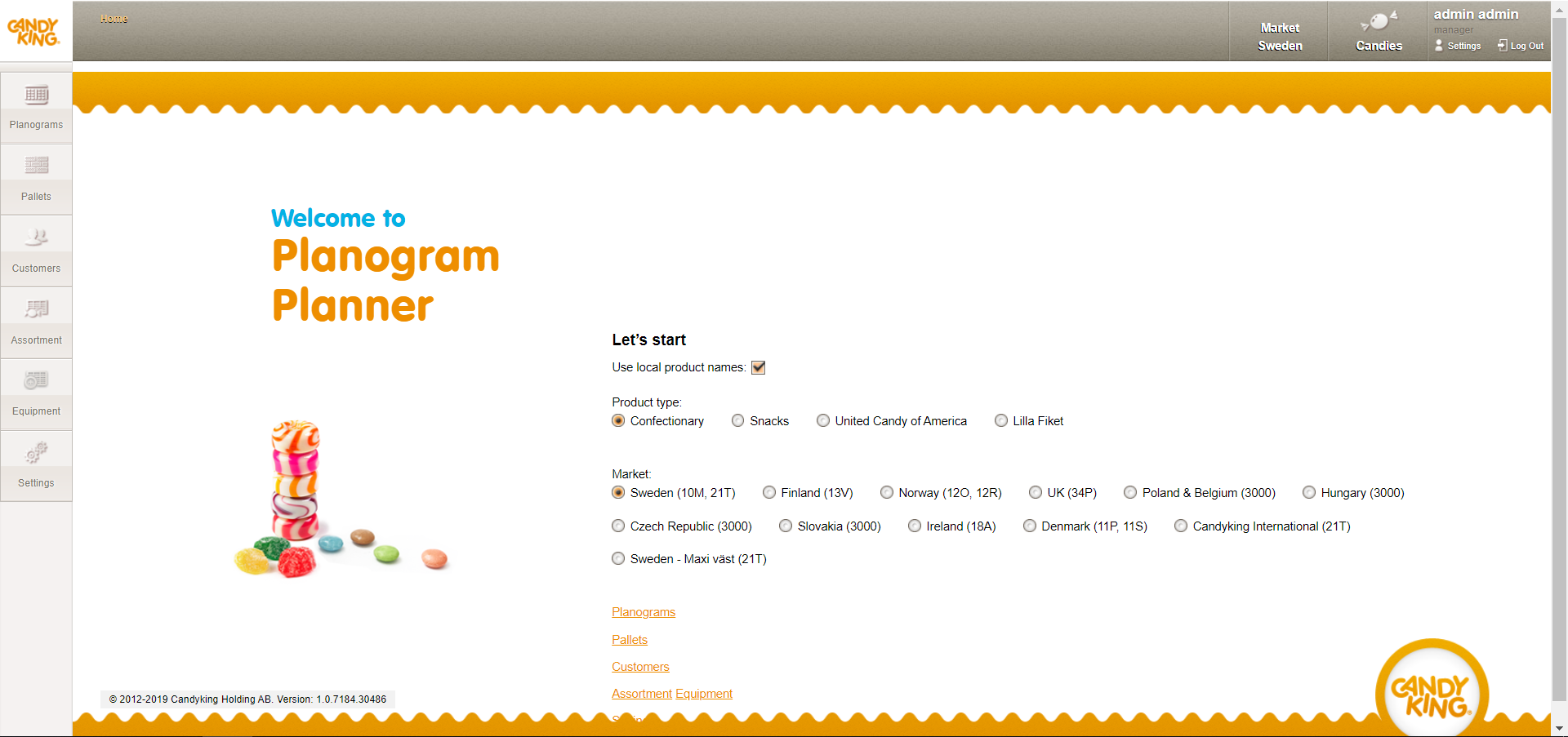

We built a planogram merchandiser from scratch that allowed for more efficient assortment management. Using the user-friendly interface, users can create planograms and fill displays with products and link them with each store.

Step 2

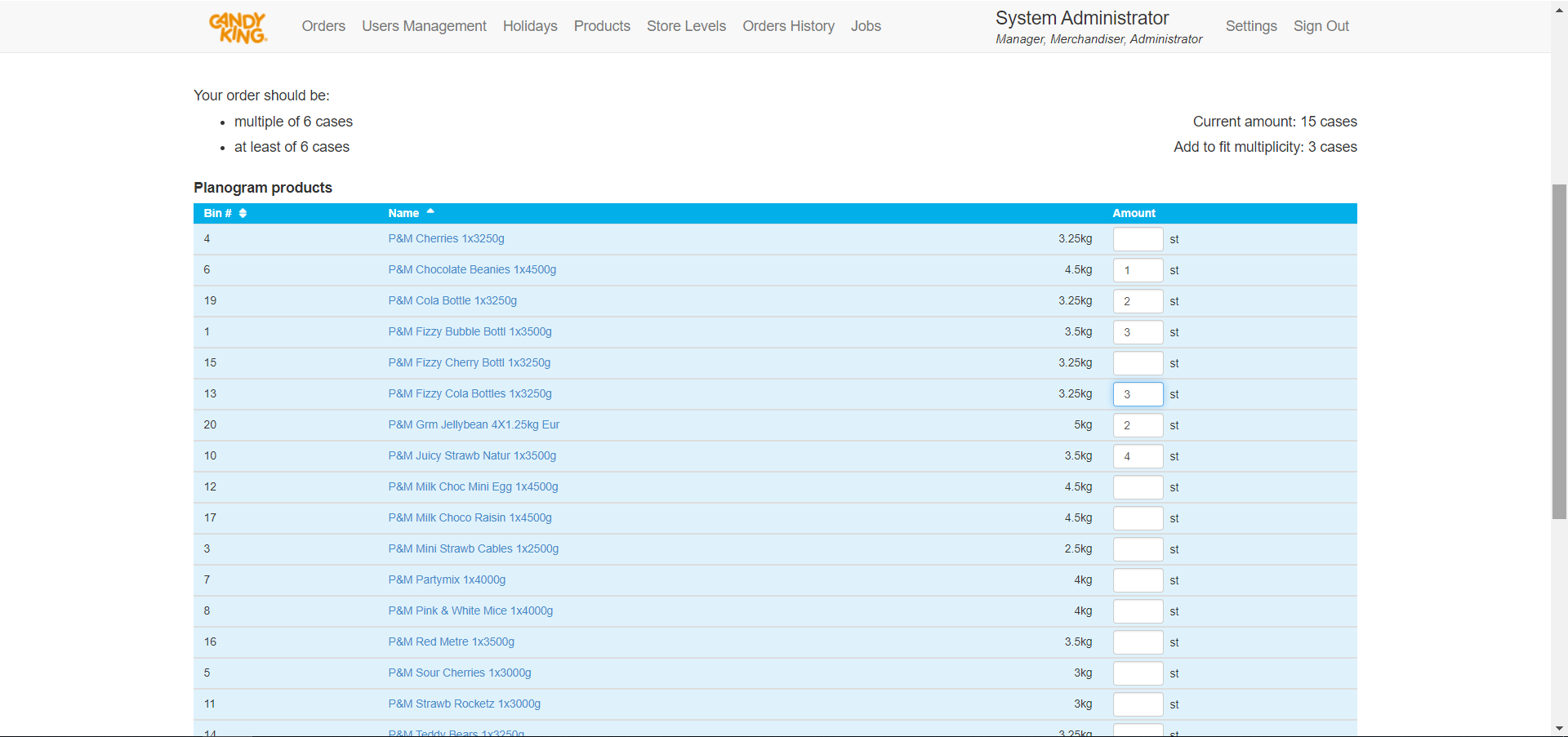

A web order system was also created from scratch, to let sales representatives place orders for the stores. The system was designed so that orders cannot go beyond a store’s assortment, and certain processes are optimized and automated by algorithms for supply chain management.

Step 3

The final, and critically important step was integrating the planogram planner, web order and SAP business management software together to ensure data accuracy and a more optimized workflow. All master data about the articles and stores is imported from SAP. And the web order system was synchronized with the planogram planner data so that sales representatives can easily view each customer’s assortment and product availability when placing orders.

Results

The new IT infrastructure yielded multiple benefits for CandyKing. The planogram planner allows them to manage their extensive assortment in a convenient and efficient way, and sales representatives no longer have to spend so much time on the entire process of ordering. The user interface and logic of the web order system adapts according to the user market, allowing different markets with different business processes use a single system adapted to their workflow.

The new web order system even allows customers themselves to make orders directly in the system and avoid involving sales representatives in some cases. This reduces labor costs for CandyKing and speeds up the entire order lifecycle.

With the planogram merchandiser, users can specify country, product type, and interior type, and then fill the visual display representation with a selected product assortment.

The web order system allows users to select which store they are placing an order for and specify the types and amounts of products desired.

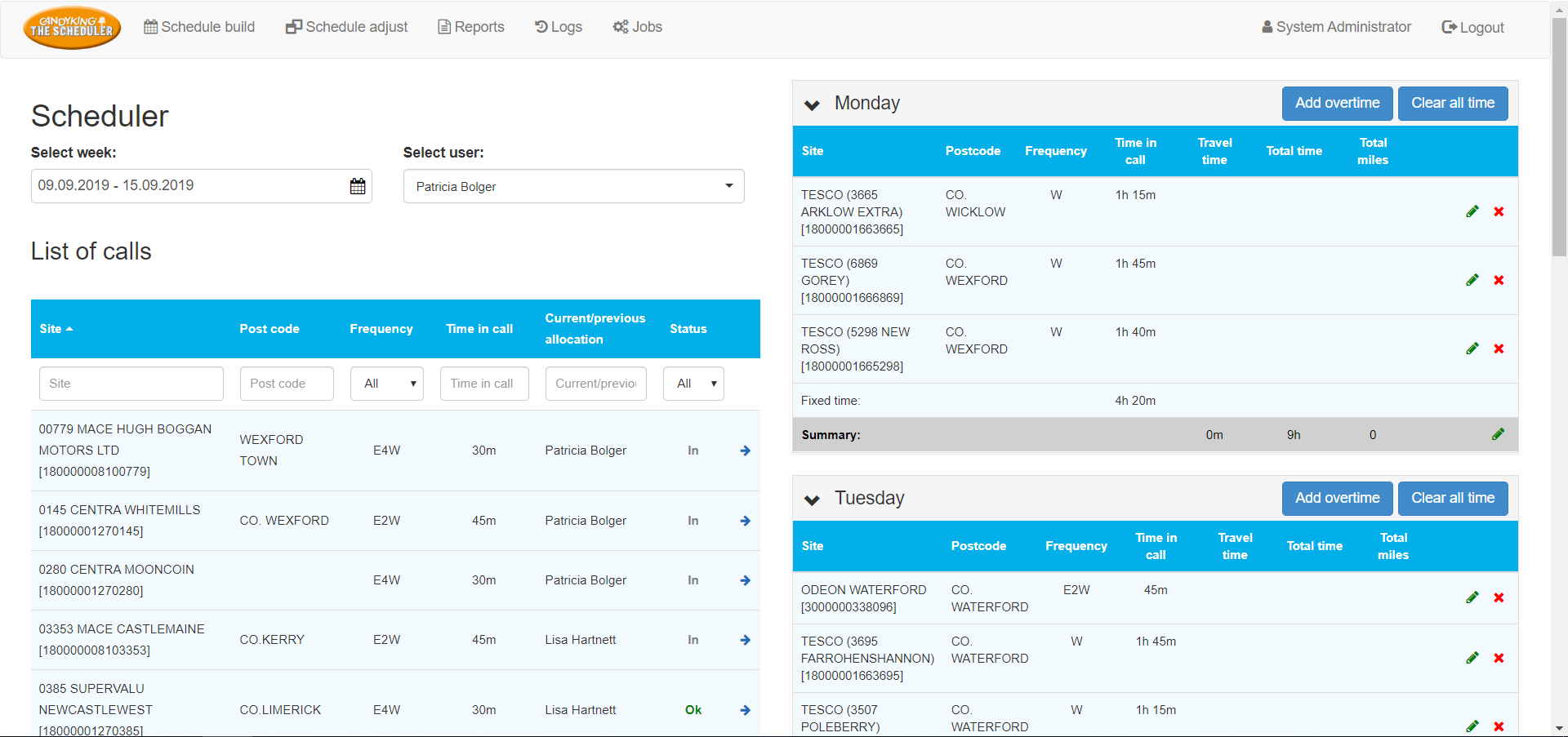

With the scheduler, users can gain an overview of planned store visits, check merchandisers’ schedules, and compare the schedules of two different merchandisers to spot an opportunity to reallocate a visit.

What’s more, since both the planogram and web order system are owned by CandyKing, they are no longer held back by user restrictions or expensive user license fees. By the end of the implementation project, there were more than 500 web order users—which would have cost them 300,000 SEK per month using the old sales automation tool.

“It was great to see how the team understood the principles of what we are trying to achieve and got their head around delivering our vision,” says Chris Hobbs, Marketing & Services Director of Cloetta UK. “The team squashed a lot in a short period of time.”